4000×2000 table.

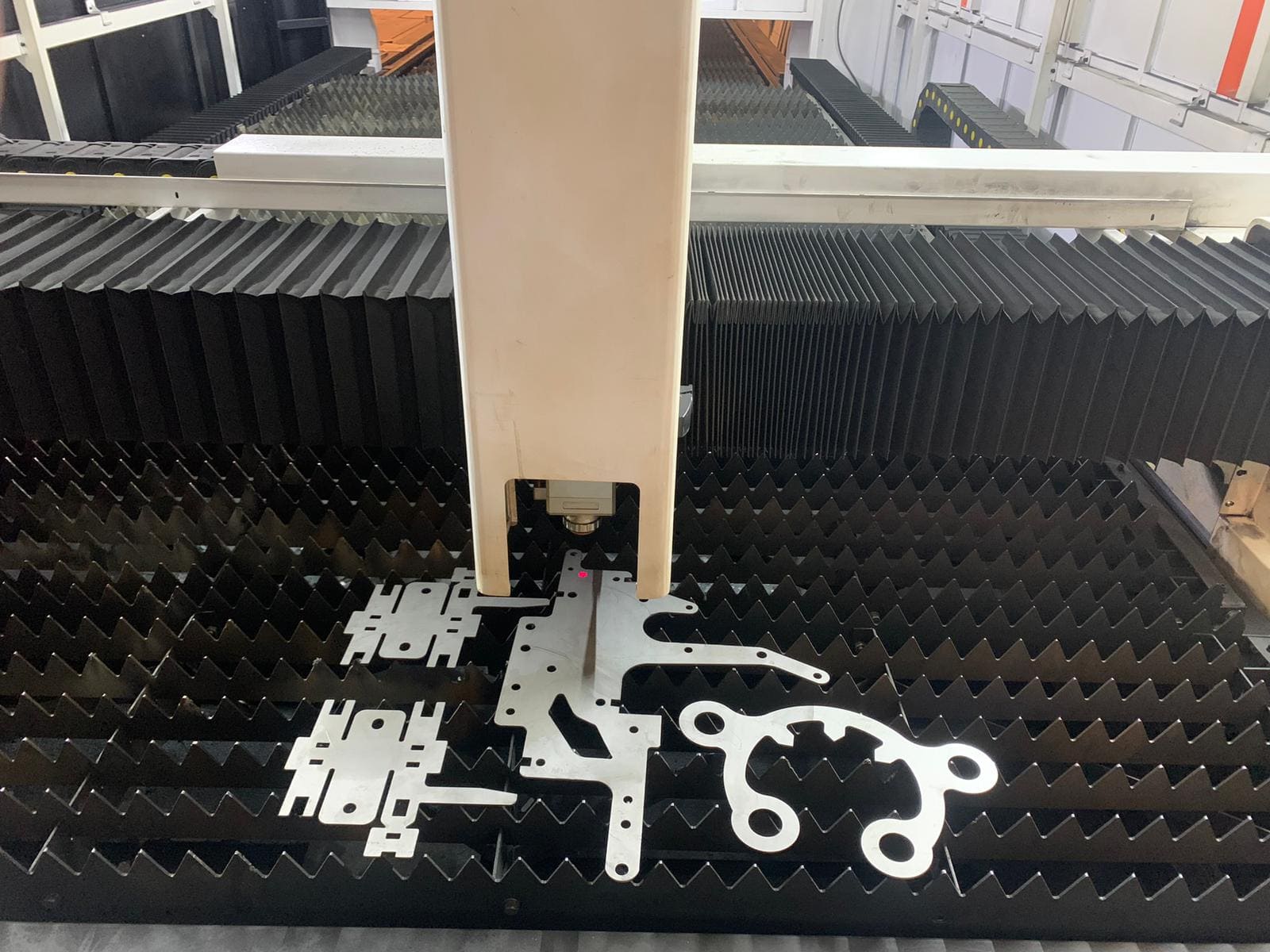

The fiber laser has already become essential in the cutting sector. It is a type of solid-state laser used by pioneering machining companies for high-precision, fast, environmentally friendly and energy-saving metal cutting.

What is Fiber Laser?

In the fiber laser, the light beam amplifier medium is an optical fiber doped with rare earth elements such as erbium, neodymium, ytterbium, diprosium, holmium, praseodymium and thulium. One or more laser diodes are used for pumping, so most fiber lasers are pumped diode lasers.

When cutting metals such as steel, the machine can release metal dust that can be harmful, especially if cutting an aluminum alloy, which also produces reflected light. For all these reasons, fiber laser machines have a protective cover.

The laser is a kind of invisible light, which cannot be calculated with the naked eye, so the optical path cannot be touched when opening the machine cover for maintenance.

It is necessary not to touch the lens frequently, and dispose of it according to certain protocols, since it contains a harmful element, zinc selenide (ZnSe).

Advantages of our fiber laser

Stability: They offer generators that provide extremely high stability for up to 100,000 hours.

Precision: The laser beam offers extremely low tolerance, which, in addition to being more productive, is much more precise.

Power: With more than 1,000 watts of power, enough to cut one-inch thick steel.

Environmentally more sustainable: The photoelectric conversion rate is 3 times higher than traditional laser cutting machine.