In our company, we specialize in the manufacture of high-quality perforated grip and anti-slip sheets.

Advantages of Perforated Sheets and Their Manufacturing

The manufacture of perforated sheets is a highly efficient process that offers a series of advantages for your projects. On the one hand, perforated sheets are known for their ability to provide grip and anti-slip, making them an ideal solution for areas where additional traction is needed.

Additionally, perforated sheets are strong and durable, making them ideal for use in industrial and commercial applications where safety and durability are essential.

Another advantage of perforated sheets is their versatility. Perforated grip plates and perforated non-slip plates can be used in a wide variety of applications, from stairs and walkways to platforms and railings. In addition, perforated sheets are also used in the manufacture of machinery and equipment, such as ventilation grilles, filters and screens.

From material selection to final finishing, each stage of the process is essential to guarantee the quality and durability of perforated sheets.

A Little More About the Process

At Depósitos Villarrobledo, we are proud to offer high quality perforated sheets that meet the highest standards of safety and durability.

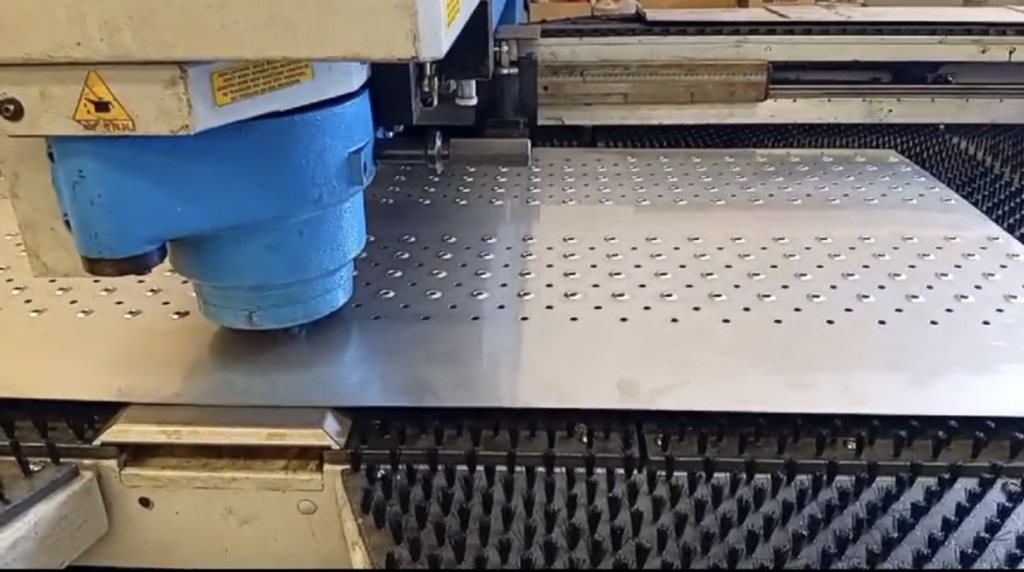

The manufacturing process of perforated sheets begins with the selection of the appropriate material, which is usually steel, stainless steel, aluminum or brass. Once the material is selected, a drilling press is used to create the holes in the sheet metal. These holes can be of different sizes and shapes, depending on the specific needs of the client.

After drilling the sheet metal, it is finished. This may include applying protective coatings, cutting the sheet metal to size, or bending the sheet metal to fit the desired shape. It is also possible to apply additional finishing processes, such as painting or polishing, to improve the appearance and anti-slip properties of the sheet.